1. Adsorption-catalysis for BTX removal

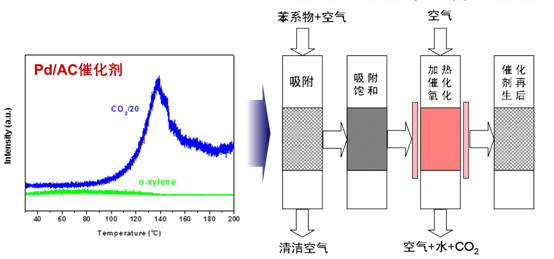

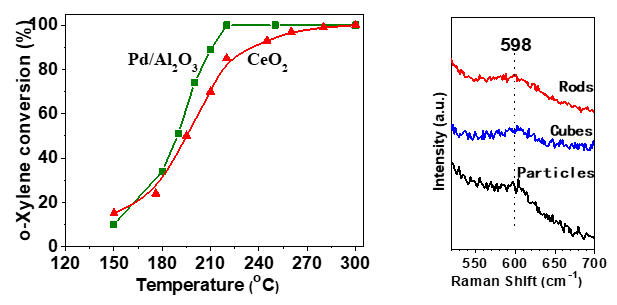

We have developed a series of Pd-based catalysts with both adsorption capacity and catalytic activity for removal of BTX. By using a Pd/AC catalyst, we established an adsorption in situ catalytic oxidation method for indoor air BTX removal, which simplifies the traditional method “adsorption – desorption – oxidation” to an “adsorption – in situ oxidation” process. The ordered mesoporous Pd/Co3O4 (3D) catalyst with more-ordered mesostructure and more well-dispersed PdO species shows excellent activity for o-xylene oxidation. Nanosized CeO2 particles, cubes, and rods are highly active for catalytic oxidation of o-xylene, and are comparable with traditional noble-metal catalysts, in which oxygen vacancy clusters play key role in the oxidation process. These catalysts are potential materials for removal of VOCs at low temperature. (Appl. Catal. B, 2013, 142-143, 72; Catal. Sci. Technol., 2016, 6, 4840; Sci. Rep., 2017, 7, 12845)

2. Removal of BTX by the combination of non-thermal plasma and catalysis

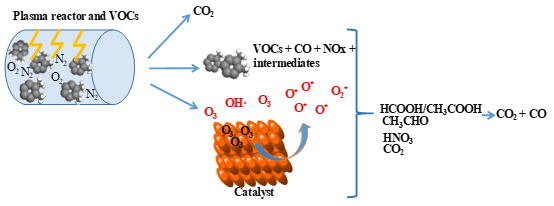

The effects of different precursors and loading amounts of Mn in the preparation of Mn/Al2O3 catalysts for use in plasma-catalytic removal of o-xylene were systematically investigated. Results showed that Mn/Al2O3 catalysts could efficiently improve o-xylene conversion with low specific energy density. .A Mn/Al2O3 catalyst prepared with a manganese acetate precursor was found to have excellent catalytic activity for o-xylene removal, with reduced formation of O3 and NOx by products. More Mn4+ species, richer lattice oxygen and the presence of the MnO2 microcrystal phase on the surface of the catalyst were responsible for the high catalytic activity in the oxidation of o-xylene. (Chem. Eng. J., 2016, 288, 406; J. Phys. Chem. C, 2016, 120, 6136)

3. Oxidation of BTX by electro-catalysis technology

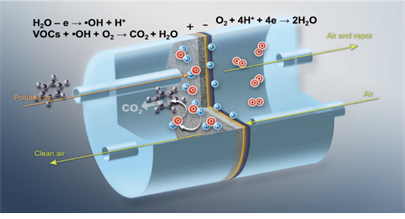

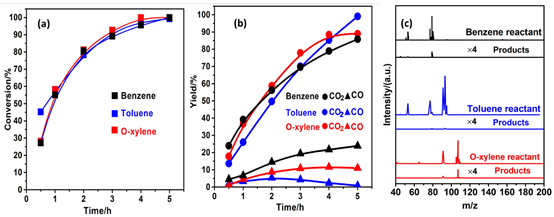

We report, for the first time, a facile gas-solid interface electrochemical oxidation method for the mineralization of benzene compounds at ambient temperature. A membrane electrode assembly (MEA) was used in an all-solid cell. The activity test results showed that 100% benzene compound conversion to CO2 (85–99%) and CO (15–1%) was achieved at the optimal cell voltage of 2.0 V at relative humidity 60%. Proton-transfer-reaction time-of-flight mass spectrometry and Fourier transform infrared spectroscopy results showed that no organic byproducts could be detected in the anodic reservoir. The electrochemical behavior of the working electrode in benzene solutions with different concentrations revealed that the benzene oxidation process was mainly an indirect oxidation process at the onset potential of OER (2.0 V vs Ag/AgCl, saturated KCl). Our findings provide evidence that the gas-solid interface electrochemical oxidation method has potential as a method for ambient VOC destruction in indoor air environments. (Chem. Eng. J., 2018, 354, 93; Chemosphere, 2019,217, 780)

24. Hua Deng, Shunyu Kang, Jinzhu Ma*, Lian Wang, Changbin Zhang, Hong He, “Role of structural defects in MnOx promoted by Ag doping in the catalytic combustion of volatile organic compounds and ambient decomposition of O3”, Environ. Sci. Technol., 53, (2019) 10871-10879.

23. Bo Zhang, Min Chen, Changbin Zhang*, Hong He, “Electrochemical oxidation of gaseous benzene on a Sb-SnO2/foam Ti nano-coating electrode in all-solid cell”, Chemosphere, 217, (2019) 780-789.

22. Lian Wang, Guangyan Xu, Jinzhu Ma, Yunbo Yu, Qingxin Ma, Kuo Liu, Changbin Zhang*, Hong He, “Nanodispersed Mn3O4/g-Al2O3 for NO2 elimination at room temperature”, Environ. Sci. Technol., 53, (2019) 10853-10862.

21. Bo Zhang, Min Chen, Lian Wang, Xu Zhao, Renzhi Hu, Hao Chen, Pinhua Xie, Changbin Zhang*, Hong He, “Electrochemical oxidation of volatile organic compounds in all-solid cell at ambient temperature”, Chem. Eng. J., 354, (2018) 93-104.

20. Hua Deng, Shunyu Kang, Jinzhu Ma*, Changbin Zhang, Hong He, “Silver incorporated into cryptomelane-type manganese oxide boosts the catalytic oxidation of benzene”, Appl. Catal. B, 239, (2018) 214-222.

19. Hua Deng, Shunyu Kang, Chunying Wang,Hong He*, Changbin Zhang*, “Palladium supported on low-surface-area fiber-based materials for catalytic oxidation of volatile organic compounds”, Chem. Eng. J., 348, (2018) 361-369.

18. Yafei Wang, Changbin Zhang*,Hong He*, “Insight into the role of Pd state on Pd-based catalysts in o-xylene oxidation at low temperature”, ChemCatChem, 10(5), (2018) 2670-2682.

17. Lian Wang, Yunbo Yu*, Hong He*, Yan Zhang, Xiubo Qin, Baoyi Wang, “Oxygen vacancy clusters essential for the catalytic activity of CeO2 nanocubes for o-xylene oxidation”, Sci. Rep., 7, (2017) 12845.

16. 胡凌霄,王莲,王飞,张长斌*,贺泓*, “Pd/γ-Al2O3催化剂催化氧化邻-二甲苯”, 物理化学学报, 33(8), (2017) 1681-1688.

15. Lian Wang, Yafei Wang, Yan Zhang, Yunbo Yu*, Hong He*, Xiubo Qin, Baoyi Wang, “Shape dependence of nanoceria on complete catalytic oxidation of o-xylene”, Catal. Sci. Technol., 6, (2016) 4840-4848.

14. Lian Wang, Changbin Zhang*, Hong He, Fudong Liu, Caixia Wang, “Effect of doping metals on OMS-2/g-Al2O3 catalysts for plasma catalytic removal of o-xylene”, J. Phys. Chem. C, 120, (2016), 6136-6144.

13. Lian Wang, Hong He*, Changbin Zhang, Yafei Wang, Bo Zhang, “Effects of precursors for manganese-loaded g-Al2O3 catalysts on plasma-catalytic removal of o-xylene”, Chem. Eng. J., 288, (2016) 406-413.

12. Jie Zhang, Changbin Zhang*, Hong He*, “Remarkable promotion effect of trace sulfation on OMS-2 nanorod catalysts for the catalytic combustion of ethanol”, J. Environ. Sci., 35 (1), (2015) 69-75.

11. 张洁,张江浩,张长斌,贺泓*, “不同晶相结构二氧化锰催化完全氧化乙醇”,物理化学学报,31(2), (2015) 353-359.

10. Yafei Wang, Changbin Zhang, Yunbo Yu, Renliang Yue, Hong He*, “Ordered mesoporous and bulk Co3O4 supported Pd catalysts for catalytic oxidation of o-xylene”, Catal. Today, 242, (2015) 294-299.

9. Yafei Wang, Changbin Zhang, Fudong Liu, Hong He*, “Well-dispersed palladium supported on ordered mesoporous Co3O4 for catalytic oxidation of o-xylene”, Appl. Catal. B, 142-143 (2013) 72-79.

8. Shaoyong Huang, Changbin Zhang*, Hong He, “Effect of pretreatment on Pd/Al2O3 catalyst for catalytic oxidation of o-xylene at low temperature”, J. Environ. Sci., 2013, 25(6) 1206-1212.

7. Lian He, Yunbo Yu*,Changbin Zhang, Hong He*, “Complete catalytic oxidation of o-xylene over CeO2 nanocubes”, J. Environ. Sci., 23, (2011) 160-165.

6. Bo Zhang, Changbin Zhang*, Hong He*, Yunbo Yu, Lian Wang, Jie Zhang, “Electrochemical synthesis of catalytically active Ru/RuO2 core-shell nanoparticles without stabilizer”, Chem. Mater., 22, (2010) 4056-4061.

5. Shaoyong Huang, Changbin Zhang, Hong He*, “In situ adsorption-catalysis system for the removal of o-xylene over an activated carbon supported Pd catalyst”, J. Environ. Sci., 21, (2009) 985-990.

4. Shaoyong Huang, Changbin Zhang, Hong He*, “Complete oxidation of o-xylene over Pd/Al2O3 catalyst at low temperature”, Catal. Today, 139, (2008)15-23.

3. 黄韶勇, 张长斌,贺泓*, “Pd/AC催化剂制备及其催化完全氧化邻-二甲苯性能”, 工业催化, 16, (2008) 38-45.

2. 王静, 吴银素*, 黄韶勇, 马子川, 贺泓, “γ-Al2O3负载的Pt, Pd催化剂上邻二甲苯的深度催化氧化”, 河北师范大学学报, 32, (2008) 73-77.

1. Lin Li, Changbin Zhang, Hong He, Junxin Liu*, “An integrated system of biological and catalytic oxidation for the removal of o-xylene from exhaust”, Catal.Today, 126, (2007) 338-344.

Group of Environmental Catalysis and Green Chemistry

You are the 1854288th visitor

Copyright Professor Hong He's Group 2019