Nitrogen oxides (NOx), emitted from stationary sources and automobile exhaust gas of fossil fuels, have been a major source of air pollution, causing a variety of environmentally harmful effects such as photochemical smog, acid rain, and haze formation. Selective catalytic reduction (SCR) of NOx with NH3 is one of the extensively used technologies for the removal of NOx from stationary and mobile sources. The development of SCR catalysts with high activity and stability which can satisfy the requirement of application is a research hotspot in this area.

1. Metal oxide catalysts for NH3-SCR reaction

1.1 Design of low V-loaded NH3-SCR catalyst with high NH3-SCR performance and study of its structure-activity relationship

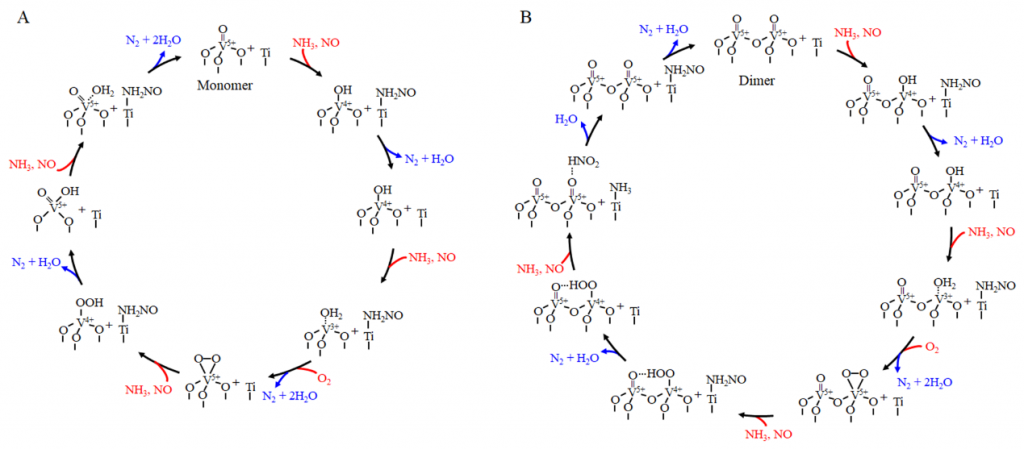

By controlling the sulfur content of the TiO2 support, the catalytically active center, oligomeric vanadia, was successfully designed and synthesized. The low-temperature SCR activity was significantly improved under low vanadium loading (1 wt.%). The whole NH3-SCR process of V-based catalysts was clarified at the atomic level with DFT calculations. The coupling effect of oligomeric vanadia not only shortens the reaction pathway for the regeneration of redox sites but also substantially reduces the overall reaction barrier of the catalytic cycle. Theoretical and experimental evidence indicates that the oligomeric vanadyl species, rather than monomeric vanadyl species, determine the NH3-SCR activity of vanadia-based catalysts, especially under low-temperature conditions. These results provide a theoretical basis for the development of high-efficiency NH3-SCR catalysts, successfully guiding the improvement of the traditional V-based catalyst and realizing the industrial application of high-efficiency V-based catalysts (Sci. Adv., 2018, 4, eaau4637; Chin. J. Catal., 2014, 35, 1438; Catal. Sci. Technol., 2020, 10, 311).

Mechanism of the standard NH3-SCR reaction. (A) Reactions over monomeric vanadia/TiO2 surfaces. (B) Reactions over dimeric vanadia/TiO2 surfaces.

1.2 Novel cerium-based oxide catalysts

Based on the in-depth understanding of the structure-activity relationship of NH3-SCR catalysts and the reaction mechanism at different temperature ranges, we established a principle for the design of NH3-SCR catalysts that involves close coupling of the redox and acid sites, which guided the development of metal oxide catalysts with excellent performance.

Through the combination of cerium and titanium oxides as redox and acidic components, respectively, a Ce-based NH3-SCR catalyst was developed for the first time; through improvement of the preparation method, the coupling of cerium and titanium oxides was enhanced, and the activity of the catalyst was promoted; through the introduction of a promoter, the redox and acidic functions were enhanced simultaneously, and the temperature window was widened; through the complete substitution of Ti with W, the obtained Ce-W oxide catalyst with closely coupled Ce and W exhibited superior performance, enabling the NOx emissions from a heavy duty diesel engine to meet the Euro V limit (Chinese V limit) in an engine bench test; through the introduction of a third component, recently we further improved the hydrothermal stability of the catalyst. (Catal. Commun., 2008, 9, 1453; Chem. Commun., 2011, 47, 8046; ChemCatChem., 2011, 3, 1286; Appl. Catal. B, 2012,115-116, 100; Chem. Commun., 2014, 50, 8445; Chin. J. Catal., 2014, 35, 1251; Catal. Commun., 2015, 59, 226; Catal. Sci. Technol., 2015, 5, 2290; Environ. Sci. Technol., 2018, 52, 11769; J. Catal., 2019, 369, 372)

2. Ion-exchanged zeolite catalyst for NH3-SCR reaction

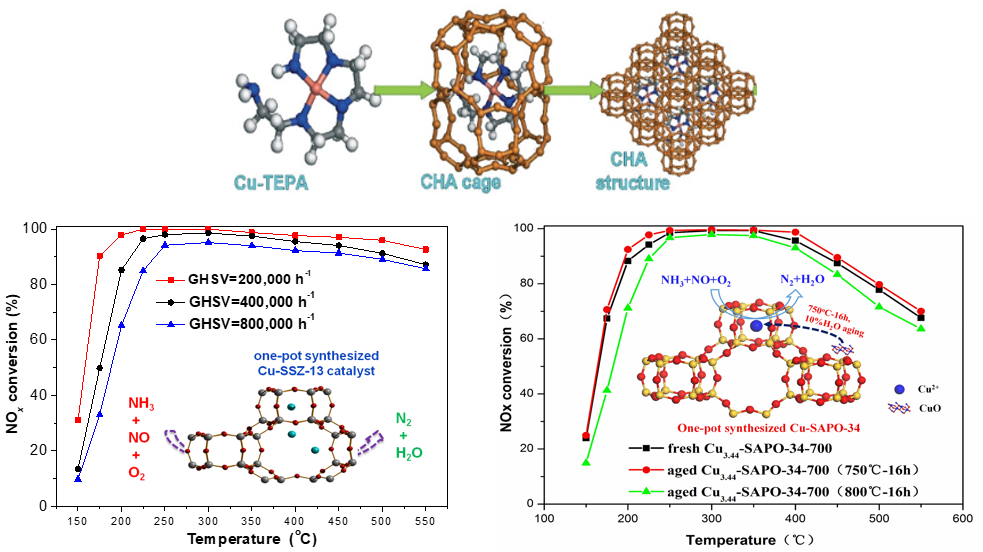

2.1 Cu-based small-pore zeolites with high NH3-SCR activity and hydrothermal stability

NH3-SCR performance of one-pot synthesized Cu-SSZ-13 and Cu-SAPO-34

2.2 NH3-SCR reaction pathway over Cu-SSZ-13

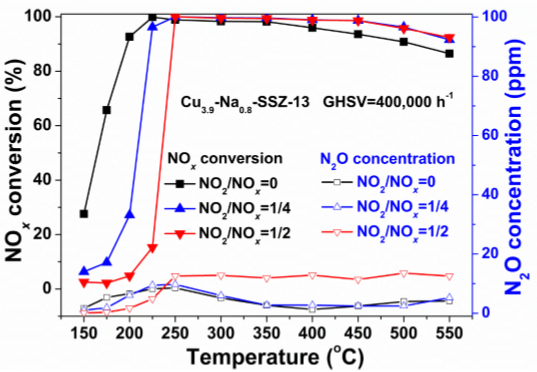

An abnormal fast SCR reaction was found over small-pore Cu-SSZ-13 zeolite: under SCR reaction conditions, the presence of NO2 inhibits NOx reduction instead of promoting it. This is because the kinetic diameter of NO2 is larger than the small pores (3.8 Å) of Cu-SSZ-13, resulting in the formation of NH4NO3 with NH4+ on the Bronsted acid sites. The accumulated NH4NO3 would block the zeolite pores and further inhibit the NO reduction at Cu active sites. When the reaction temperature is above the decomposition temperature of NH4NO3, the NO reduction is recovered. By comparing the standard and fast SCR over the H-SSZ-13 support, it was found that NO can only be reduced at Cu active sites under standard SCR conditions. Under fast SCR conditions, however, NO can be also reduced at acid sites through the fast SCR reaction. (Catal. Sci. Technol., 2014, 4, 1104; J. Phys. Chem. C, 2018, 122, 25948)

2.3 Deactivation mechanism during hydrothermal aging of Cu-SSZ-13

Compared to fresh Cu-SSZ-13 (FR-Cu-SSZ-13), Cu-SSZ-13 hydrothermally aged at 750 ℃ (HA-Cu-SSZ-13) showed marked deactivation of NOx efficiency and a narrower operating temperature window. The activity of Cu-SSZ-13 hydrothermally aged at 750 ℃ decreased progressively in the presence of SO2 (SA-Cu-SSZ-13), only achieving a maximum NOx conversion of 85%. The characterization results of H2-TPR, EPR, DRIFTS, XRD, and NMR techniques showed that the accumulation of CuOx clusters from active Cu2+ and zeolite framework dealumination are the main reasons for hydrothermal aging deactivation. The presence of SO2 increased the acidity of the aging atmosphere, therefore accelerating the destruction of the zeolite structure and transformation of Cu2+ to CuOx clusters. (Catal. Today, 2019, 320, 84; Appl. Catal. B: Environ., 2020, 266, 118655)

59) Yulong Shan, Jinpeng Du, Yunbo Yu, Wenpo Shan, Xiaoyan Shi*, Hong He*, “Precise control of post-treatment significantly increases hydrothermal stability of in-situ synthesized Cu-zeolites for NH3-SCR reaction”, Appl. Catal. B, 266, (2020) 118655.

58) Yulong Shan, Wenpo Shan, Xiaoyan Shi, Jinpeng Du, Yunbo Yu*, Hong He*, “A comparative study of the activity and hydrothermal stability of Al-rich Cu-SSZ-39 and Cu-SSZ-13”, Appl. Catal. B, 264, (2020) 118511.

57) Na Zhu, Wenpo Shan*, Zhihua Lian, Yan Zhang, Kuo Liu, Hong He, “A superior Fe-V-Ti catalyst with high activity and SO2 resistance for the selective catalytic reduction of NOx with NH3”. J. Hazard. Mater., 382, (2020) 120970.

56) Zhihua Lian, Shaohui Xin, Na Zhu, Qiang Wang, Jun Xu, Yan Zhang, Wenpo Shan*, Hong He, “Effect of treatment atmosphere on the vanadium species of V/TiO2 catalysts for the selective catalytic reduction of NOx with NH3”. Catal. Sci. Technol, 10, (2020) 311-314.

55) Yulong Shan, Xiaoyan Shi, Jinpeng Du, Zidi Yan, Yunbo Yu, Hong He*, “SSZ-13 synthesized by solvent-free method: A potential candidate for NH3-SCR catalyst with high activity and hydrothermal stability”, Ind. Eng. Chem. Res., 58, (2019) 5397-5403.

54) Yulong Shan, Xiaoyan Shi, Zidi Yan, Jingjing Liu, Yunbo Yu, Hong He*, “Deactivation of Cu-SSZ-13 in the presence of SO2 during hydrothermal aging”, Catal. Today, 320, (2019) 84-90.

53) Guangyan Xu, Jinzhu Ma, Lian Wang, Zhihui Lv, Shaoxin Wang, Yunbo Yu*, Hong He*, “The mechanism of the H2 effect on NH3-SCR over Ag/Al2O3: Kinetic and DRIFTS studies”, ACS Catal., 9, (2019) 10489-10498.

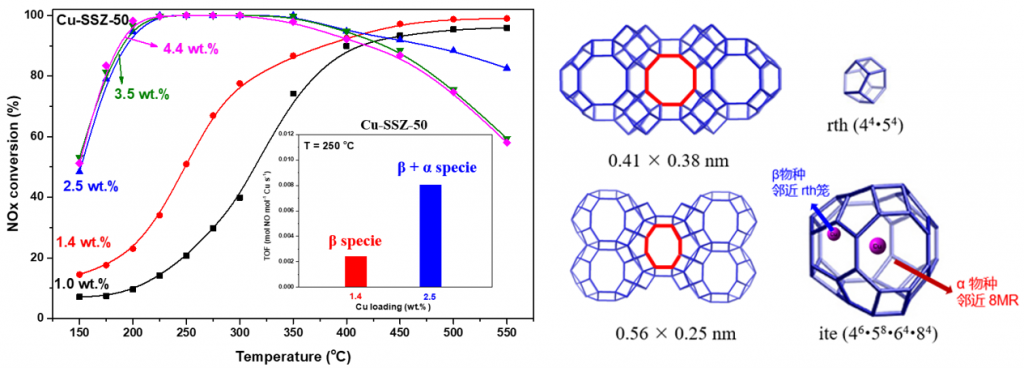

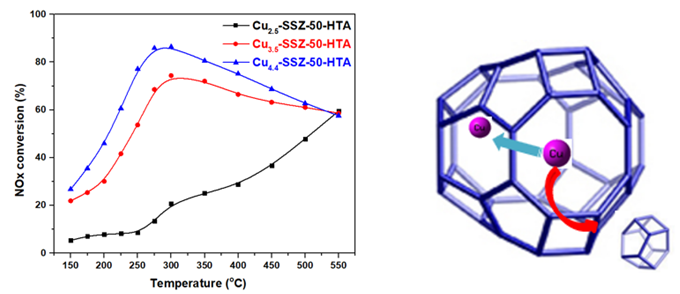

52) Yulong Shan, Xiaoyan Shi, Jinpeng Du, Yunbo Yu, Hong He*, “Cu-exchanged RTH-type zeolites for NH3-selective catalytic reduction of NOx: Cu distribution and hydrothermal stability”, Catal. Sci. Technol., 9, (2019) 106-115.

51) Guangzhi He, Bo Zhang, Hong He*, Xueyan Chen, Yulong Shan, “Atomic-scale insights into zeolite-based catalysis in N2O decomposition”, Sci. Total Environ., 673, (2019) 266-271.

50) Kuo Liu, Zidi Yan, Hong He, Qingcai Feng, Wenpo Shan*, “The effect of H2O on a vanadium-based catalyst for NH3-SCR at low temperatures: a quantitative study of the reaction pathway and active sites”, Catal. Sci. Technol., 9, (2019) 5593-5604.

49) Kuo Liu, Hong He*, Yunbo Yu, Zidi Yan, Weiwei Yang, Wenpo Shan, “Quantitative study of the NH3-SCR pathway and the active site distribution over CeWOx at low temperatures”, J. Catal., 369, (2019) 372-384.

48) Wen Xie, Yunbo Yu*, Hong He*, “Shape dependence of support for the NOx storage and reduction catalyst”, J. Environ. Sci. 75, (2019) 396-407.

47) Na Zhu, Zhihua Lian, Yan Zhang, Wenpo Shan*, Hong He, “The promotional effect of H2 reduction treatment on the low-temperature NH3-SCR activity of Cu/SAPO-18”, Appl. Surf. Sci., 483 (2019) 536-544.

46) Na Zhu, Zhihua Lian, Yan Zhang, Wenpo Shan*, Hong He, “Improvement of low-temperature catalytic activity over hierarchical Fe-Beta catalysts for selective catalytic reduction of NOx with NH3”, Chin. Chem. Lett., 30 (2019) 867-870.

45) Zhihua Lian, Wenpo Shan, Meng Wang, Hong He*, Qingcai Feng*, “The balance of acidity and redox capability over modified CeO2 catalyst for the selective catalytic reduction of NO with NH3”, J. Environ. Sci. 79, (2019) 273-279.

44) Guangzhi He, Zhihua Lian, Yunbo Yu, Yang Yang, Kuo Liu, Xiaoyan Shi, Zidi Yan, Wenpo Shan, Hong He*, “Polymeric vanadyl species determine the low-temperature activity of V-based catalysts for the SCR of NOx with NH3”, Sci. Adv., 4, (2018) eaau4637.

43) Zidi Yan, Xiaoyan Shi*, Yunbo Yu, Hong He, “Alkali resistance promotion of Ce doped vanadium-titanic based NH3-SCR catalysts”, J. Environ. Sci., 73, (2018) 155-161.

42) Jingjing Liu, Xiaoyan Shi, Yulong Shan, Zidi Yan, Wenpo Shan, Yunbo Yu, Hong He*, “Hydrothermal stability of CeO2-WO3-ZrO2 mixed oxides for selective catalytic reduction of NOx by NH3”, Environ. Sci. Technol., 52, (2018) 11769-11777.

41) Yulong Shan, Xiaoyan Shi, Guangzhi He, Kuo Liu, Zidi Yan, Yunbo Yu, Hong He*, “Effect of NO2 addition on the NH3-SCR over small-pore Cu-SSZ-13 zeolites with varying Cu loadings”, J. Phys. Chem. C, 122, (2018) 25948-25953.

40) Wenpo Shan, Yang Geng, Yan Zhang, Zhihua Lian, Hong He*, “A CeO2/ZrO2-TiO2 catalyst for the selective catalytic reduction of NOx with NH3”, Catalysts, 8, (2018) 592-603.

39) Zhihua Lian, Wenpo Shan, Yan Zhang, Meng Wang, Hong He*, “Morphology-dependent catalytic performance of NbOx/CeO2 catalysts for selective catalytic reduction of NOx with NH3”, Ind. Eng. Chem. Res., 57, (2018) 12736-12741.

38) Fudong Liu, Wenpo Shan, Zhihua Lian, Jingjing Liu, Hong He*, “The smart surface modification of Fe2O3 by WOx for significantly promoting the selective catalytic reduction of NOx with NH3”, Appl. Catal. B, 230, (2018) 165-176.

37) Can Niu, Xiaoyan Shi, Fudong Liu, Kuo Liu, Lijuan Xie, Yan You*, Hong He*, “High hydrothermal stability of Cu-SAPO-34 catalysts for the NH3-SCR of NOx”, Chem. Eng. J., 294, (2016) 254-263.

36) Can Niu, Xiaoyan Shi*, Kuo Liu, Yan You, Shaoxin Wang, Hong He, “A novel one-pot synthesized CuCe-SAPO-34 catalyst with high NH3-SCR activity and H2O resistance”. Catal. Commun., 81, (2016) 20–23.

35) Weiwei Yang, Fudong Liu*, Lijuan Xie, Zhihua Lian, Hong He*, “The Effect of V2O5 Additive on the SO2 Resistance of Fe2O3/AC Catalyst for NH3-SCR of NOx at Low Temperatures”, Ind. Eng. Chem. Res., 55, (2016) 2677-2685.

34) Shipeng Ding, Fudong Liu*, Xiaoyan Shi, Hong He*, “Promotional effect of Nb additive on the activity and hydrothermal stability for the selective catalytic reduction of NOx with NH3 over CeZrOx catalyst”, Appl. Catal. B, 180, (2016) 766-774.

33) Xiaoyan Shi*, Hong He, Lijuan Xie, “The effect of Fe species distribution and acidity of Fe-ZSM-5 on the hydrothermal stability and SO2 and hydrocarbons durability in NH3-SCR reaction”, Chin. J. Catal., 36, (2015) 649-656.

32) Shipeng Ding, Fudong Liu*, Xiaoyan Shi, Kuo Liu, Zhihua Lian, Lijuan Xie, Hong He*, “Significant promotion effect of Mo additive on novel Ce-Zr mixed oxide catalyst for the selective catalytic reduction of NOx with NH3”, ACS Appl. Mater. Interfaces., 7, (2015) 9497-9506.

31) Lijuan Xie, Fudong Liu, Xiaoyan Shi, Feng-Shou Xiao, Hong He*, “Effects of post-treatment method and Na co-cation on thehydrothermal stability of Cu–SSZ-13 catalyst for the selective catalytic reduction of NOx with NH3”, Appl.Catal. B., 179, (2015) 206-212.

30) Kuo Liu, Fudong Liu, Lijuan Xie, Wenpo Shan, Hong He*, “DRIFTS study of a Ce-W mixed oxide catalyst for the selective catalytic reduction of NOx with NH3”, Catal. Sci. Technol., 5, (2015) 2290-2299.

29) Zhihua Lian, Fudong Liu*, Hong He*, Kuo Liu, “Nb-doped VOx/CeO2 catalyst for NH3-SCR of NOx at low temperatures”, RSC Adv., 5, (2015) 37675-37681.

28) Wenpo Shan, Fudong Liu*, Yunbo Yu, Hong He*, Chenglin Deng, Xinyun Zi, “High-efficiency reduction of NOx emission from diesel exhaust using a CeWOx catalyst”, Catal. Commun., 59, (2015) 226-228.

27) Zhihua Lian, Fudong Liu, Hong He*, “Effect of preparation methods on the activity of VOx/CeO2 catalysts for the selective catalytic reduction of NOx with NH3”, Catal. Sci. Technol., 5(1), (2015) 389-396.

26) Zhihua Lian, Jinzhu Ma, Hong He*, “Decomposition of high-level ozone under high humidity over Mn–Fe catalyst: The influence of iron precursors”, Catal. Commun., 59, (2015) 156-160.

25) Zhihua Lian, Fudong Liu, Hong He*, “Enhanced activity of Ti-modified V2O5/CeO2 catalyst for the selective catalytic reduction of NOx with NH3”, Ind. Eng. Chem. Res., 53, (2014) 19506-19511.

24) Wenpo Shan, Fudong Liu, Yunbo Yu, Hong He*, “The use of ceria for the selective catalytic reduction of NOx with NH3”, Chin. J. Catal., 35, (2014) 1251-1259.

23) Fudong Liu, Wenpo Shan, Dawei Pan, Tengying Li, Hong He*, “Selective catalytic reduction of NOx by NH3 for heavy-duty diesel vehicles”, Chin. J. Catal., 35, (2014) 1438-1445.

22) Fudong Liu, Yunbo Yu, Hong He*, “Environmentally-benign catalysts for the selective catalytic reduction of NOx from diesel engines: Structure-activity relationship and reaction mechanism aspects”, Chem. Commun., 50 (62), (2014) 8445-8463.

21) Zhihua Lian, Fudong Liu, Hong He*, Xiaoyan Shi, Jiansong Mo, Zhongbiao Wu, “Manganese–niobium mixed oxide catalyst for the selective catalytic reduction of NOx with NH3 at low temperatures”, Chem. Eng. J., 250, (2014) 390-398.

20) Lijuan Xie, Fudong Liu, Kuo Liu, Xiaoyan Shi, Hong He*, "Inhibitory effect of NO2 on the selective catalytic reduction of NOx with NH3 over one-pot synthesized Cu-SSZ-13 catalyst", Catal. Sci. Technol., 4, (2014) 1104-1110.

19) Lijuan Xie, Fudong Liu, Limin Ren, Xiaoyan Shi, Fengshou Xiao, Hong He*, "Excellent performance of one-pot synthesized Cu-SSZ-13 catalyst for the selective catalytic reduction of NOx with NH3", Environ. Sci. Technol., 48, (2014) 566-572.

18) Fudong Liu, Hong He*, Lijuan Xie, "XAFS study on the specific deoxidation behavior of iron titanate catalyst for the selective catalytic reduction of NOx with NH3", ChemCatChem., 5, (2013) 3760-3769.

17) Xiaoyan Shi, Fudong Liu, Lijuan Xie, Wenpo Shan, Hong He*, "NH3‑SCR performance of fresh and hydrothermally aged Fe-ZSM‑5 in standard and fast selective catalytic reduction reactions", Environ. Sci. Technol., 47, (2013) 3293-3298.

16) Fudong Liu, Wenpo Shan, Zhihua Lian, Lijuan Xie, Weiwei Yang, Hong He*, "Novel MnWOx catalyst with remarkable performance for low temperature NH3-SCR of NOx", Catal. Sci. Technol., 3, (2013) 2699-2707.

15) Fudong Liu, Hong He*, Zhihua Lian, Wenpo Shan, Lijuan Xie, Kiyotaka Asakura, Weiwei Yang, Hua Deng, "Highly dispersed iron vanadate catalyst supported on TiO2 for the selective catalytic reduction of NOx with NH3", J. Catal., 307, (2013) 340-351.

14) Fudong Liu, Kiyotaka Asakurab*, Pengyang Xie, Jianguo Wang,Hong He*, "An XAFS study on the specific microstructure of active species in iron titanate catalyst for NH3-SCR of NOx", Catal. Today, 201, (2013) 131-138.

13) Wenpo Shan, Fudong Liu*, Hong He*, Xiaoyan Shi, Changbin Zhang, "An environmentally-benign CeO2-TiO2 catalyst for the selective catalytic reduction of NOx with NH3 in simulated diesel exhaust", Catal. Today, 184, (2012) 160-165.

12) Wenpo Shan, Fudong Liu*, Hong He*, Xiaoyan Shi, Changbin Zhang, "A superior Ce-W-Ti mixed oxide catalyst for the selective catalytic reduction of NOx with NH3", Appl. Catal. B, 115-116, (2012) 100-106.

11) Fudong Liu, Hong He*, Changbin Zhang, Wenpo Shan, Xiaoyan Shi, "Mechanism of the selective catalytic reduction of NOx with NH3 over environmental-friendly iron titanate catalyst", Catal. Today, 175(1), (2011) 18-25.

10) Wenpo Shan, Fudong Liu*, Hong He*, Xiaoyan Shi, Changbin Zhang, "The Remarkable Improvement of a Ce-Ti based Catalyst for NOx Abatement, Prepared by a Homogeneous Precipitation Method", ChemCatChem., 3, (2011) 1286-1289.

9) Wenpo Shan, Fudong Liu*, Hong He, Xiaoyan Shi, Changbin Zhang, "Novel cerium-tungsten mixed oxide catalyst for the selective catalytic reduction of NOx with NH3", Chem. Commun., 47, (2011) 8046-8048.

8) Fudong Liu, Kiyotaka Asakura, Hong He*, Yongchun Liu,Wenpo Shan, Xiaoyan Shi, Changbin Zhang, "Influence of calcination temperature on iron titanate catalyst for the selective catalytic reduction of NOx with NH3", Catal. Today, 164, (2011) 520-527.

7) Fudong Liu, Kiyotaka Asakura, Hong He*, Wenpo Shan, Xiaoyan Shi, Changbin Zhang, "Influence of sulfation on iron titanate catalyst for the selective catalytic reduction of NOx with NH3", Appl. Catal. B, 103, (2011) 369-377.

6) Fudong Liu, Hong He*, "Structure-activity relationship of iron titanate catalysts in the selective catalytic reduction of NOx with NH3", J. Phys. Chem. C, 114, (2010) 16929-16936.

5) Fudong Liu, Hong He*, "Selective catalytic reduction of NO with NH3 over manganese substituted iron titanate catalyst: Reaction mechanism and H2O/SO2 inhibition mechanism study", Catal. Today, 153,(2010) 70-76.

4) Fudong Liu, Hong He*, Changbin Zhang, Zhaochi Feng, Lirong Zheng, Yaning Xie, Tiandou Hu, "Selective catalytic reduction of NO with NH3 over iron titanate catalyst: Catalytic performance and characterization", Appl. Catal. B, 96, (2010) 408-420.

3) Fudong Liu, Hong He*, Yun Ding, Changbin Zhang, "Effect of manganese substitution on the structure and activity of iron titanate catalyst for the selective catalytic reduction of NO with NH3", Appl. Catal. B, 93, (2009) 194-204.

2) Wenqing Xu, Hong He*, Yunbo Yu, "Deactivation of a Ce/TiO2 catalyst by SO2 in the selective catalytic reduction of NO by NH3", J. Phys. Chem. C, 113, (2009) 4426-4432.

1) Wenqing Xu, Yunbo Yu, Changbin Zhang, Hong He*, "Selective catalytic reduction of NO by NH3 over a Ce/TiO2 catalyst", Catal. Commun., 9, (2008) 1453-1457.

Group of Environmental Catalysis and Green Chemistry

You are the 1854288th visitor

Copyright Professor Hong He's Group 2019